Custom Continuous Furnaces and Ovens

Continuous heat treatment furnaces are fully customizable and are available in various options to meet your project’s exact specifications. Custom continuous furnaces and ovens are ideal for high-capacity work envelopes, offering heavy-duty conveying systems, supports, door seals, hinges, and actuators. State-of-the-art control systems and HMIs deliver precision, accuracy, and unprecedented results.

Contact us for more information on the custom continuous furnace or oven system that best suits your specification requirements, or call us at 800-275-5152, and we will be happy to assist you with your continuous oven and furnace questions.

Rotary Hearth Furnaces

Kleenair's rotary hearth furnaces feature a rotating worktable that transfers workpieces from the loading door to the unloading door. Temperature and rotational speed can be modified to meet customer requirements.

View Rotary Hearth Furnace OptionsRoller Hearth Furnaces

Our roller hearth furnaces feature motor-driven rollers for a "conveyor belt" to transport workpieces from the loading door to the unloading door. Heavy-duty roller bearings are designed to minimize load for a long working life.

View Roller Hearth Furnace OptionsWalking Beam Furnaces & Ovens

Kleenair walking beam furnaces and ovens use an automated, multi-rail "walking beam" system to move workpieces through the process area one step at a time. Robust designs and engineering ensure reliable and consistent movement.

View Walking Beam Furnace & Oven OptionsPusher Furnaces & Ovens

Pusher furnaces and ovens can operate at the highest temperatures of our continuous furnaces. Parts or materials are placed on trays, which are pushed through the furnace on rails by hydraulic or pneumatic cylinders for reliable processing.

View Pusher Furnace & Oven OptionsTable of Contents

Custom Continuous Furnace & Oven Applications

Kleenair’s continuous furnaces and ovens are specifically designed to adjust to your exact design specifications and are used for the following applications:

- Metal injection molding

- Atmospheric controls

- Glass

- Annealing

- Brazing

- Metalizing

Types of Custom Continuous Furnaces and Ovens

Custom Rotary Hearth Furnaces

Kleenair’s rotary hearth furnaces feature a rotating worktable that transfers workpieces from the loading door to the unloading door. Temperature and rotational speed can be modified to match your process requirements.

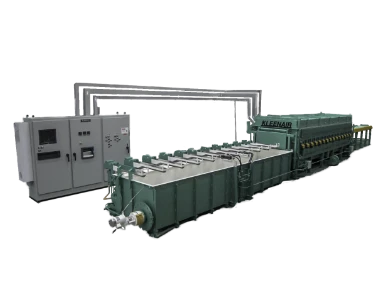

Custom Roller Hearth Furnaces

Our roller hearth furnaces feature motor-driven rollers for a “conveyor belt” to transport workpieces from the loading door to the unloading door. Heavy-duty roller bearings are designed to minimize load for a long working life.

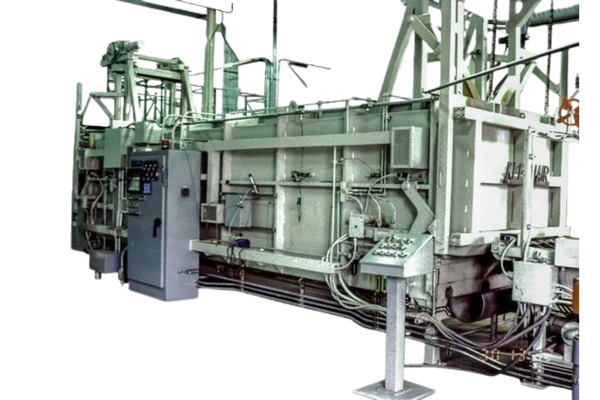

Custom Walking Beam Furnaces & Ovens

Kleenair walking beam furnaces and ovens use an automated, multi-rail “walking beam” system to move workpieces through the process area one step at a time. Robust designs and engineering ensure reliable, consistent movement and precise heat times.

Custom Walking Beam Furnaces & Ovens

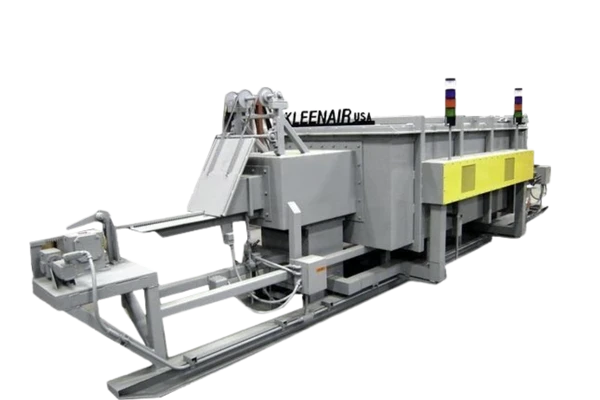

Custom Pusher Furnaces & Ovens

Pusher furnaces and ovens can operate at the highest temperatures of our continuous furnaces. Parts or materials are placed on trays, which are pushed through the furnace on rails by hydraulic or pneumatic cylinders for reliable processing.

Custom Pusher Furnaces & Ovens

Custom Continuous Furnace & Oven Advantages

While each of our custom continuous furnaces and ovens is designed for a different application, they all provide the following advanced quality features:

- High-capacity work envelopes

- Refractories specially designed for extremely high operating temperatures

- Heavy-duty conveying systems and supports

- The industry’s best door seals, door hinges, and door actuators

- Natural gas or electric heat

- State-of-the-art control systems/HMIs for enhanced usability

- Heavy-duty construction for durability and longevity

- NFPA 86 and OSHA compliance

State-Of-The-Art Controls for Enhanced Usability

Kleenair’s continuous furnaces and ovens are among the best and most dependable on the market. With a host of exclusive, proprietary features, these furnaces deliver unparalleled performance and usability in even the most demanding industries and applications. All our continuous ovens and furnaces meet NFPA 86 and OSHA requirements. Advanced continuous oven and furnace features include the following:

- Robust conveying systems and support structures

- Premium quality door components

- Innovative controls and HMIs

- State-of-the-art combustion systems and temperature uniformity

Why Choose Kleenair Products for your Custom Continuous Furnace or Oven Needs?

With over 50 years of experience designing, engineering, and manufacturing custom industrial furnaces and ovens, Kleenair Products can produce a custom aerospace heat treatment furnace based on your exact needs and specifications. Some of the advantages of working with Kleenair for your custom-built industrial furnace and oven needs include:

- Unrivaled Experience & Expertise

- Unique Custom Options

- Premium Quality Materials

- Ongoing Support Throughout the Life of the Furnace or Oven

Contact Kleenair for Custom Continuous Furnaces and Ovens Today

Kleenair is one of the nation's primary industrial furnace manufacturers. We can design, engineer, manufacture, and install a custom continuous furnace that meets your unique application and performance requirements.

Request a quote on a custom continuous furnace or oven, call us at 800-275-5152, or contact Kleenair to discuss your project today.

Featured:

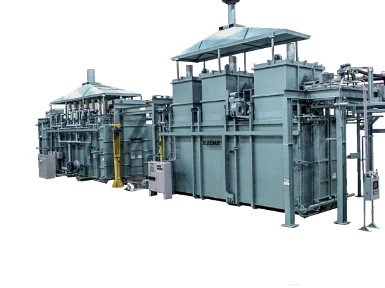

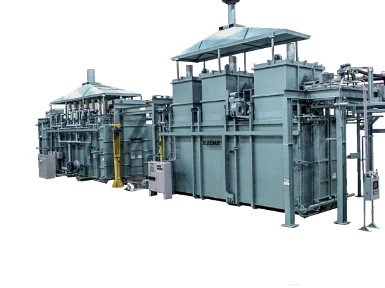

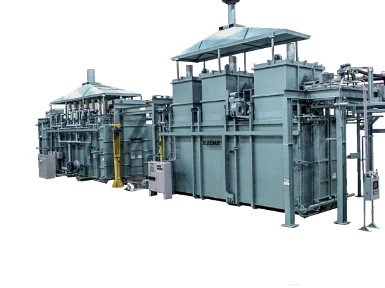

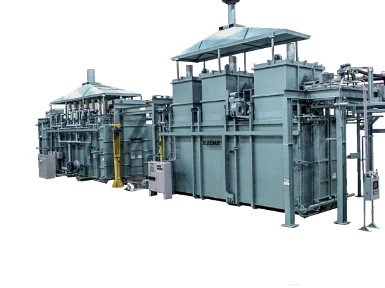

Continuous Heat Treat Furnace and Quench

A continuous austenitize quench and temper heat treat system. Built in 2001, this automated system is used to treat steel components for the military and defense. Visit our photo gallery for more Continuous Furnace and Oven photos.